|

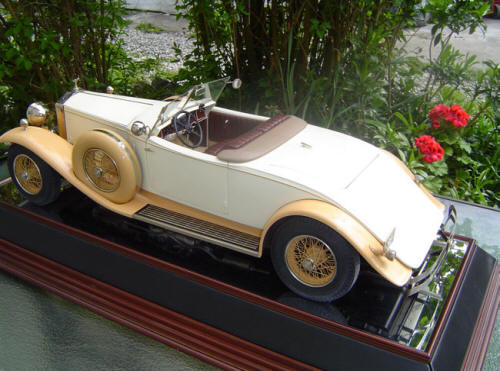

1:8th. Rolls-Royce

Henley Brewster Phantom II model:

Chassis:

The main frame and many of it's component parts, were used from the

Italian Pocher kit of the English RR Phantom II. This included the

exhaust system, axles, brake drums, engine, steering wheel and column,

spoke wheels, tires, radiator, flying lady emblem, headlights, side

fender lights, and horn assembly.

Chassis

Modifications:

As our model was to be of the American "left hand drive" version of the

Phantom II chassis, many modifications had to be made to the Pocher

parts. As the steering column and the controls had to be switched to

the other side, it was necessary to modify many of the engine parts, in

particular the exhaust system. In some cases, new molds had to be

made, in order to produce the new castings.

Henley

Brewster Body:

The

particular design

of Brewster body that we decided to replicate was featured in the

excellent book by John Webb

DeCampi "Rolls-Royce in America". It appears that a few of the

original motor cars have been restored or maintained in excellent

condition by a number of collectors in the U.S. today.

The floor board section

from the Pocher kit was also used to tie the four fenders together into

one large assembly. The Henley wings are a unique design, and do not

resemble the Phantom II wings in the Pocher kit, so they had to be

prefabricated from plexiglas and body fillers. Once this complete

assembly was finished, a rubber mold was made. Using various epoxy

and polyester materials, castings were made of the floor and fender

assembly.

The engine compartment

bulkhead from the Pocher kit was modified, and used as part of the new

body shell. With the use of plexiglas, metal and body fillers, the

original plug for the main body was built. This assembly contained the

aperture for the rear hatch, and the two side doors. A rubber mold for

this assembly was made, enabling us to make castings in various epoxy

and polyester materials. The two main doors, the small hatch

compartment door, and the hatch door were made the same way, and rubber

molds were produced.

Bumpers:

The bumpers are individually built from flat brass strip and

tube. Jigs and dies were made to form the unique shapes, which were

then soldered together. The spring strip assemblies behind the bumpers

were built in the same way. Bumpers were then polished, copper plated,

and then nickel plated. Spot lights on the bumper were from metal

casting we did in house.

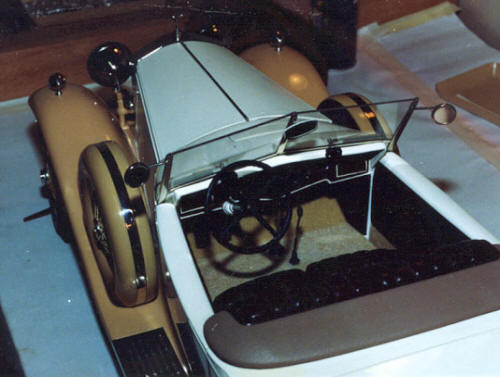

Windscreen:

One of the very distinctive features of the Henley Brewster

is this centre split screen. It consists of three vertical elements,

and one horizontal base frame, molded to the shape of the body. The two

plexiglas panes are open at the top. The centre vertical element has a

streamlined section at the bottom. We manufactured these screen

assemblies individually with brass channel, box section and solder.

Polishing, copper and nickel plating gave these pieces their final

finish. Rear view mirrors, and screen spotlights were also scratch

built and finished in the same way.

Dashboard:

Many hours were spent replicating the classic shape of the

Henley dashboard assembly. Full size artwork of the instrument dials

were created, reflecting the smallest detail such as the RR logo.

These were then reduced, and printed in 1:8 scale. The dash was

covered with a micro thin wood veneer, and the instruments put behind

clear acrylic with metal bezels. Simulated switches and push/pull

knobs were then added. Gear shift, handbrake and foot controls are

all built to the exact specification of these classics. The interior

door handles were hand built from brass, and the exterior door handles

are metal castings that we actually cast ourselves. All these parts

were nickel plated.

Seats

and door trims:

Seat cushions and backs

were made from plexiglas and body filler to form the basic ribbed

shape. As was the door trims, and inside walls of the cockpit. They

were than covered in the finest glove leather we could find. The

leather was then treated with the required colour of die, to match the

interior trim.

Doors:

The doors were not made to open, as it was possible to see the interior

with them closed. Where possible, we try to keep moving parts to the

minimum, in order to guard against rough handling. Unfortunately, the

only way it was possible to see the interior of the rear hatch

compartment, was to make the hatch open. If we had fixed it in the

open position, you would never get to appreciate the beautiful lines of

the back of the vehicle.

Engine

Compartment:

This was also the case

with the engine compartment. It was necessary to make the hood or

bonnet lift, in order to see the engine detail.

Model

Base:

In

order to see the underside of the model, we decided to cover the base

surface with an acrylic mirror. Leather covered panels surround the

plinth, inside the clear acrylic cover. Wood moldings form the main

base, which has a draw in the front, containing a brief history of

the actual Henley Brewster, and also the model.

HOME

ROLLS-ROYCE

CONTACT

|